Projects

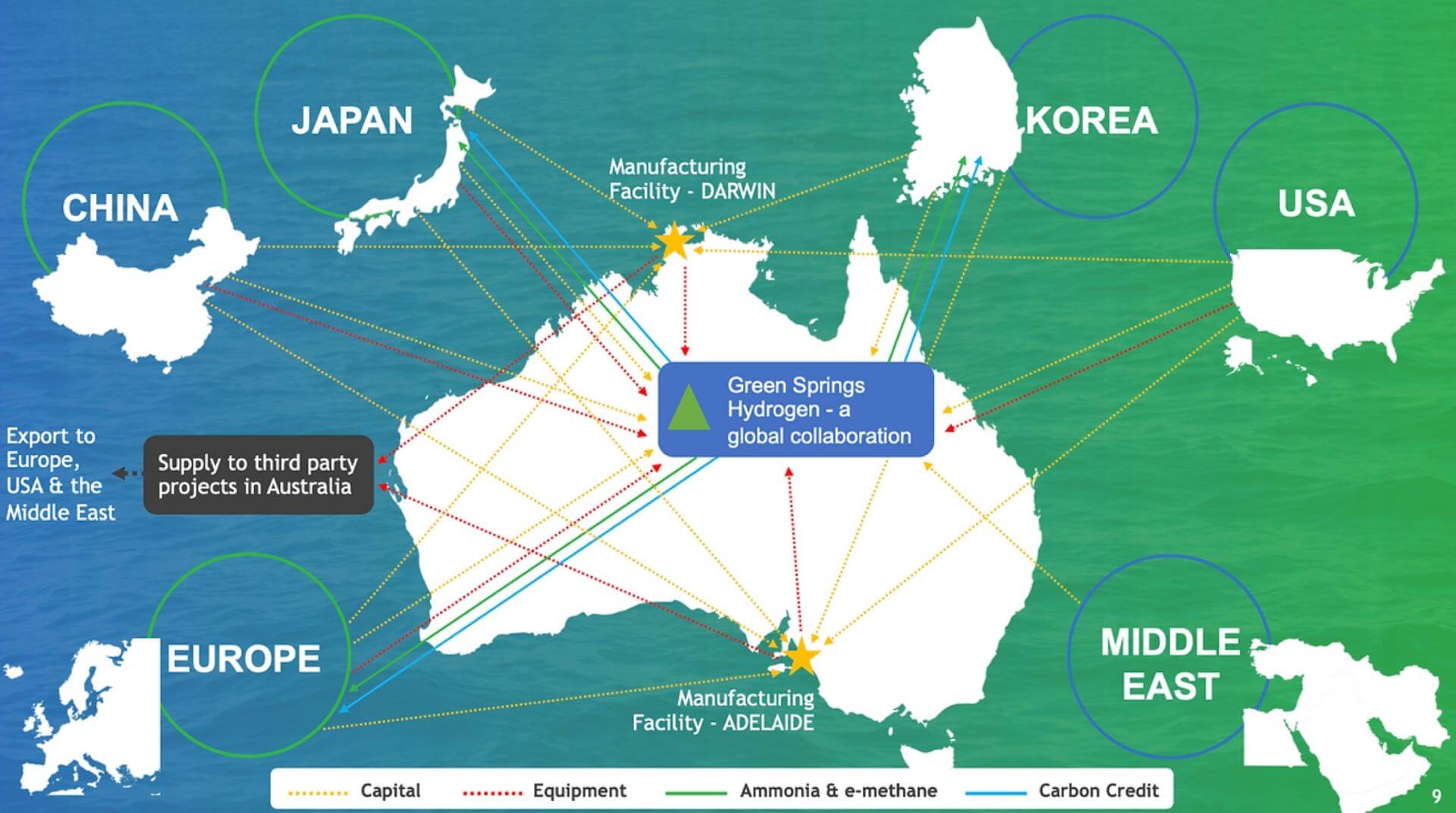

Green Springs Hydrogen and Integrated Derivatives Production

The project is a 10GW off-grid green hydrogen project which consists of a series of hydrogen production modules (HPM). Each HPM comprises:

- A photovoltaic (PV) solar system

- A concentrated parabolic trough (CPT) solar thermal heater

- A water manufacturing unit (WMU) which includes carbon capture

- A purpose designed electrolyser.

At full capacity the Project is designed to produce:

-

1,128,600 kg/day of hydrogen from a 10,000MW electrolyser plant]

- 10,260 kl/day of water

- 281 GJ/ day of thermal energy for use as a heat processor in water production

- 80,000MWh of solar power/ day with an 8,000MW (DCp) PV system.

Green Springs Hydrogen and Integrated Derivatives Production is a 10GW integrated off grid renewables based green hydrogen and chemical production project in the Northern Territory of Australia. This project will produce green hydrogen-based products such as liquid hydrogen, e-methanol, e-kerosine, fuel ammonia and a range of industrial chemicals that currently use grey or blue hydrogen in their production process.

Project Highlights

Founding Consortium Established

The founding consortium has been established and is now being expanded to include members through the full supply chain.

Completion of the feasibility study

The project’s feasibility study has been completed.

FEED underway

The first stage of the Front End Engineering Design (FEED) has been completed and the second stage is underway.

An integrated project

The project includes the manufacturing of upstream equipment, midstream and downstream hydrogen production, and delivery of green hydrogen derivatives.

Modular hydrogen production project

The project is based on a modular system that uses proven technology in each module. This creates a large-scale, stand-alone off-grid system which can produce renewable hydrogen without requiring a ground or ocean-based water source.

Fully off grid

Green Springs is not connected to utility services and does not require significant government investment in support infrastructure. This means the project can be located at points of high solar resource and deployed quickly.

World’s lowest LCOH

The project has been ideally located to produce green hydrogen at the lowest Levelised Cost of Hydrogen (LCOH) in the world. The location has multiple benefits including:

- Independently identified as one of the world’s lowest cost production locations.

- Location on flat land near facilities at Alice Springs allowing large scale chemical production.

- An abundance of land available with no shortage of land for expansion.

- It is below a cyclone path, which will affect many announced Australian hydrogen projects.

Multiple transport options

to port

Green Springs will be the closest project to the main demand centres of Japan and Korea.

It is in close proximity to multiple transport modes including the national highway, the national rail freight line and a gas pipeline that are connected to Darwin’s Middle Arm precinct facilities and interstate networks.

Green hydrogen derivatives production

The project will produce green hydrogen-based products such as liquid hydrogen, e-methanol, e-kerosine, fuel ammonia and a range of industrial chemicals that currently use grey or blue hydrogen in their processes.

Supply Chain